How Does Vacuum Leak Tester for Pet Bottles Work?

It also complies with various national and international testing standards such as ASTM D 4991-07(2015), ASTM F 2338-09(2013), ASTM D6653, ASTM D3078 and ASTM D5094.

How it works:

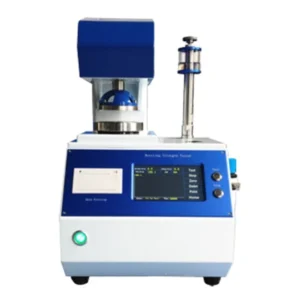

The Cell Instruments vacuum leak detection system specifically designed for PET bottles is a high-quality machine that consists of a clear acrylic vacuum chamber and system, a control valve, and an indicator gauge. Bottles to be tested are simply placed in the clear acrylic vacuum tank, the lid is closed and vacuum engaged. You can then choose which testing method to use based on your company’s standards and requirements. A complete test can be accomplished in just a matter of seconds with immediate results!

A vacuum leak tester is considered to be one of the quality lab testing instruments used in the PET bottle industry. By testing the vacuum leaks present in PET bottles, manufacturers can easily ensure accuracy in the product. The digital model of the Cell Instruments vacuum leak tester for PET bottles comes with a microprocessor-based timer for the accuracy and repeatability of the testing results. The samples will be tested through an easy vacuum mechanism and users will get accurate testing results. The powder-coated Havel gray and blue combination finish will make this vacuum leak testing instrument more durable. With the use of this high-quality lab testing instrument, manufacturers will easily conduct vacuum leak tests and ensure accuracy in the testing results.

If you are working in the PET bottle industry, then this vacuum leak testing equipment will work best for you in determining the leak integrity of the product. By using this high-quality lab testing instrument the manufacturers of the bottle industry can deliver leak-resistant products to the customers. This will eventually help to reduce the high product rejection rates that occur due to poor quality products.

Cell Instruments is a leading vacuum leak tester manufacturer and offers the best vacuum leak tester price to clients. This digital vacuum leak tester model will help the users to view the testing results on a digital display. Besides this, users can also monitor pressure and timer with the help of digital controls embedded in this lab testing instrument. It comes with an in-built calibration facility and vacuum gauge for easy pressure monitoring. Manufacturers of the PET bottle industry can effectively make use of this lab testing instrument to test the vacuum leaks present in the PET bottles.

Testing Standards (Methods):

ASTM D 4991-07(2015) – Destructive Leak integrity test by vacuum method for empty rigid containers. Leaks are detected under differential pressure conditions.

ASTM F 2338-09(2013) – Non-destructive Detection of Leaks in Packages by Vacuum Decay Method.

ASTM D6653 – Test methods for determining the effects of high altitude on packaging systems by vacuum method.

ASTM D5094 – Test methods for gross leakage of liquids from containers with threaded or lug-style closures for rigid and semi-rigid containers.

ASTM D3078 – Test Method for Determination of Leaks in Flexible Packaging by Bubble Emission.

Specification

| Test Range | 0~-90 KPa |

| Chamber | Acrylic Cylinder Shape |

| Test Space | Φ270*H210mm (Inside Usable) |

| Compressed Air | 0.7MPa (Prepared by user) |

| Power | 110~220V 50/60Hz |

Features

- Microprocessor based timer for accuracy and repeatability

- Sample testing through easy vacuum mechanism

- Inlet Vacuum Pressure setting and Pre-set Timer functions incorporated

- Changeable Timer Units in Hrs:min:sec

- Inbuilt Calibration facility

- Vacuum gauge for easy pressure monitoring

评价

目前还没有评价